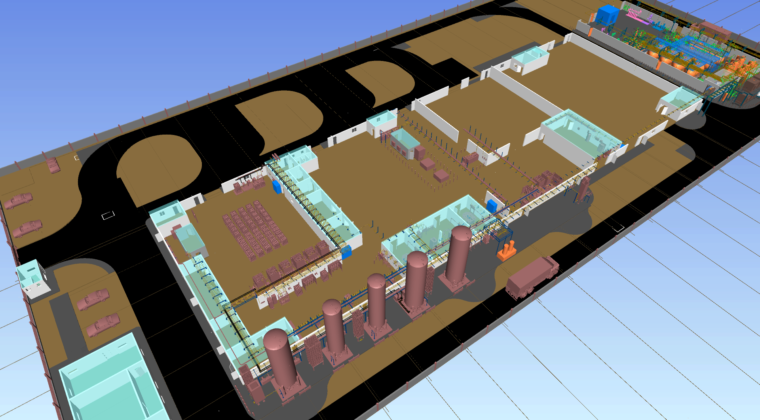

3D Modelled Cylinder Filling Plant by IGAS Technology Solutions Ltd (IGAS).

A major part of our latest project execution strategy is to prepare a 3D Model of any new cylinder filling plant we engineer.

The key benefits of a 3D Modelled Cylinder Filling Plant includes;

- Provides the client and all stakeholders with a clear view of the future plant. This includes the ability to ‘walk through’ the virtual plant.

- Ensures optimised product flow and ergonomics at the design phase.

- Enables IGAS to prepare very detailed layouts and equipment lists for the plant (at design phase), including but not limited to;

- Tank farm layout.

- Pipework routes and distances.

- Cable routes and distances.

- Filling hall layout ensuring optimised product flow, efficiency and ergonomics.

- Ensures equipment selection (dimensions) are designed to “fit” with no clashes.

- Detailed information eases the installation phase.

https://www.igas-ts.com/about-us/

As IGAS, our portfolio includes full turnkey plant solutions through to equipment only.

Applications served and expertise provided includes;

- Turnkey plant (process, mechanical and electrical) design & engineering

- Manufacture and installation (globally)

- Industrial, Medical, Speciality Gas and Refrigerant Cylinder Filling Solutions

- Mono and mixture gases cylinder filling solutions

- Cryogenic equipment and cylinder filling solutions

- Trailer filling and decanting system

- Gas generation systems

- Pressure reduction and gas supply systems

- CO2 recovery, liquefaction and filling solutions

- Fixed and mobile (containerised) plant

- Manual, semi-automatic and automatic plant