Overview

- Manual, semi-automatic, fully automatic

- Single gas and mixtures filling

- Factory built and tested units for ‘plug and play’

- Modular design, tailored to suit

- Filling pressures up to 450bar (design pressures up to 600bar)

- O2 shock tested products (BAM and/or CTE)

- Turnkey or part turnkey

- Sequential or blended mixtures filling

- Low cost of ownership

- Engineered and fully documented

FOR FURTHER INFORMATION SEE BELOW LINKS

Cryogenic Reciprocating Pump Skids

- Single speed – Dual speed – Variable speed

- Capacity to suit demand

- Cooldown probe

- Cavitation probe

- Seal heater

- Pulsation damper

- Check valve

- Monel wetted parts on request

- O2 compatible lubrication for oxidising gases

FOR FURTHER INFORMATION SEE BELOW LINKS

Line Manifolds (Safety Panels)

- Pressure transmitter and high high pump trip

- Local pressure gauge

- Filter

- Low temperature protection

- Block discharge relief valve

- Maintenance valves for isolation and venting

- Thermal expansion and pump overrun buffer

- Options for larger buffer systems

- Options for automatic buffer control

- Options for instrument gas system from buffer (nitrogen)

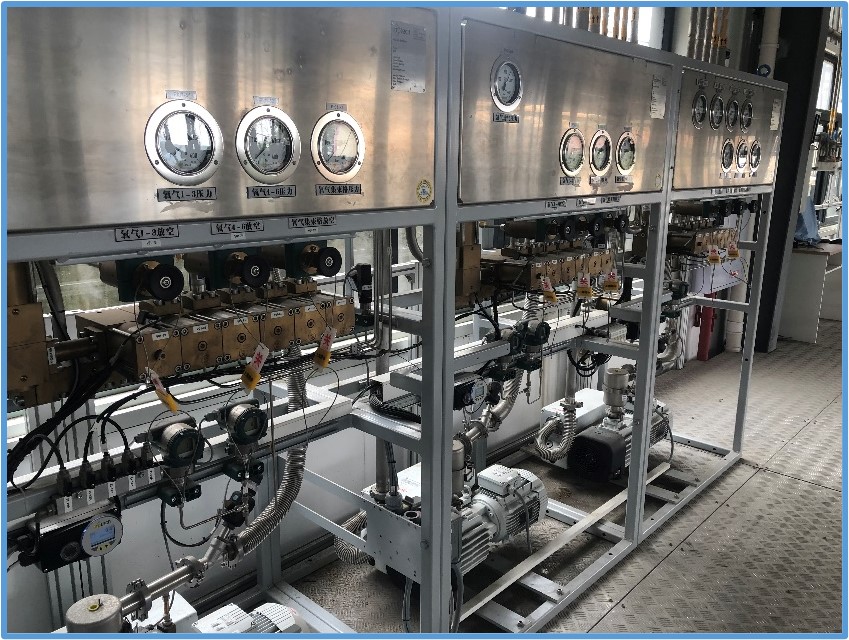

Filling Modules & Vacuum

- Filling Modules & Vacuum

- Temperature compensated filling for gaseous filling

- Gravimetric filling for liquefied gases

- Options for mass flow and reference cylinder filling

- Filling valves, with option for double block and bleed (for each gas)

- Vacuum valve

- Vent valve

- Dual and triple pressure filling options

- Pressure transmission high range

- Pressure transmission low range

- Fill station selection valves

- Vacuum systems

- capacity to suit

- over pressure protected

- vacuum pressure transmission

- Filtration

- Block and bleed valve

- O2 compatible lubrication as an option

- Vent Silencers

Filling Stations

- Single cylinder filling

- Rack filling (linear)

- Pallet filling (size to suit)

- MCP/Bundle/Quad filling

- Trolley filling

- Winter Fill (for warmer climates)

- Pigtail and flexible hose options

- Filling connections to suit local requirement, with options for heatsinks

- Options for hose isolation valves

- Walkways

- Pallet lifting

- Safety cages