IGAS Technology Solutions and Rawabi Integrated Gas Co implement AiFill plant control system module into the Rawabi Integrated Gas Co cylinder filling plant.

AiFill plant control system module is aligned with the Kingdom of Saudi Arabia 2030 vision ensuring Rawabi Integrated Gas Co lead the supply of Industrial Gases and technology transfer within the Saudi Arabia industrial market.

AiFill, which interfaces directly with the iTrack system is a fully integrated PLC Control system which manages the automatic filling of Rawabi Integrated Gas Co assets, (Cylinders & Bundles).

Key features;

- AiFill is based on Siemens S7-1500 PLC’s and is programmed using Siemens TIA software which ensures high reliability, high levels of safety, global support and availability.

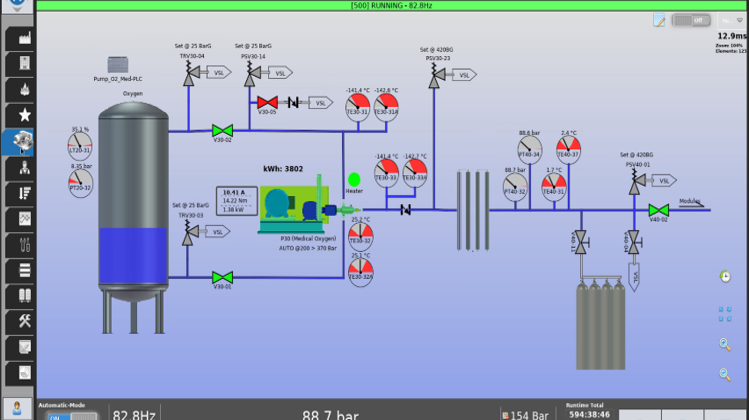

The large touch screen HMI’s provide;

- Entire plant view, including (for example), pressure, temperature, pump and valve status.

- Zoomed view of specific “module” elements of the process.

- Key Performance Indicators (KPI) dashboard view

- Fill control: Pressure / temperature compensation, Gravimetric and Mass flow techniques.

- Recipe builder: Graphical interface allows fast easy creation and modification of recipes (by Rawabi Integrated Gas Co) , broken down into discrete steps such as; vent, vacuum & fill.

- Sequence builder: Graphical interface allows fast easy creation and modification (by Rawabi Integrated Gas Co) of sequences.

- Resource (supply systems, filling modules, filling stations) queuing: AiFill provides a graphical display of the resource availability and allows changes / priories to be made.

- Pump Control: Pumps are started from a PID like Interface showing key parameters. Pump starts are an automatic sequence including opening of valves / waiting for cooldown / variable speed control when running.

- Fill record certificate: A certificate is generated per fill, along with labels per batch / cylinder.

- Quality Control: Certificate of Analysis (CoA) & Certificate of Conformance (CoC) are generated automatically post analysis.

- Cylinder manager: System contains a list of each cylinder type which is used for operator selection, record generation and for modifying fill, vent & vacuum times (authorisation level

- controlled).

- Trending: Enables Rawabi Integrated Gas Co to interrogate the system P&ID’s to view trends and therefore potential areas for investigation.

- Preventative maintenance: Resettable counters record various elements of the filling plant; valves cycles, pump run hours, buffer cylinder pressure cycles thus providing valuable maintenance information.

- Access control: Specific access rights are generated for varying levels of authority.

- Multi language: System is available in multi-language.

- Global remote support: Providing fast, diagnosis and therefore rectification of issues.

https://igph.net/downloads/filling-modules-gases-cylinder/aifill-control-system/

https://www.igas-ts.com/service/industrial-gas-cylinder-filling/